ISO 9001 implementation: Mandatory documents and records

Mandatory documents and records when it comes to the ISO 13485 implementation are previously discussed. It is turned to discuss the same regarding ISO 9001:2015 implementation.

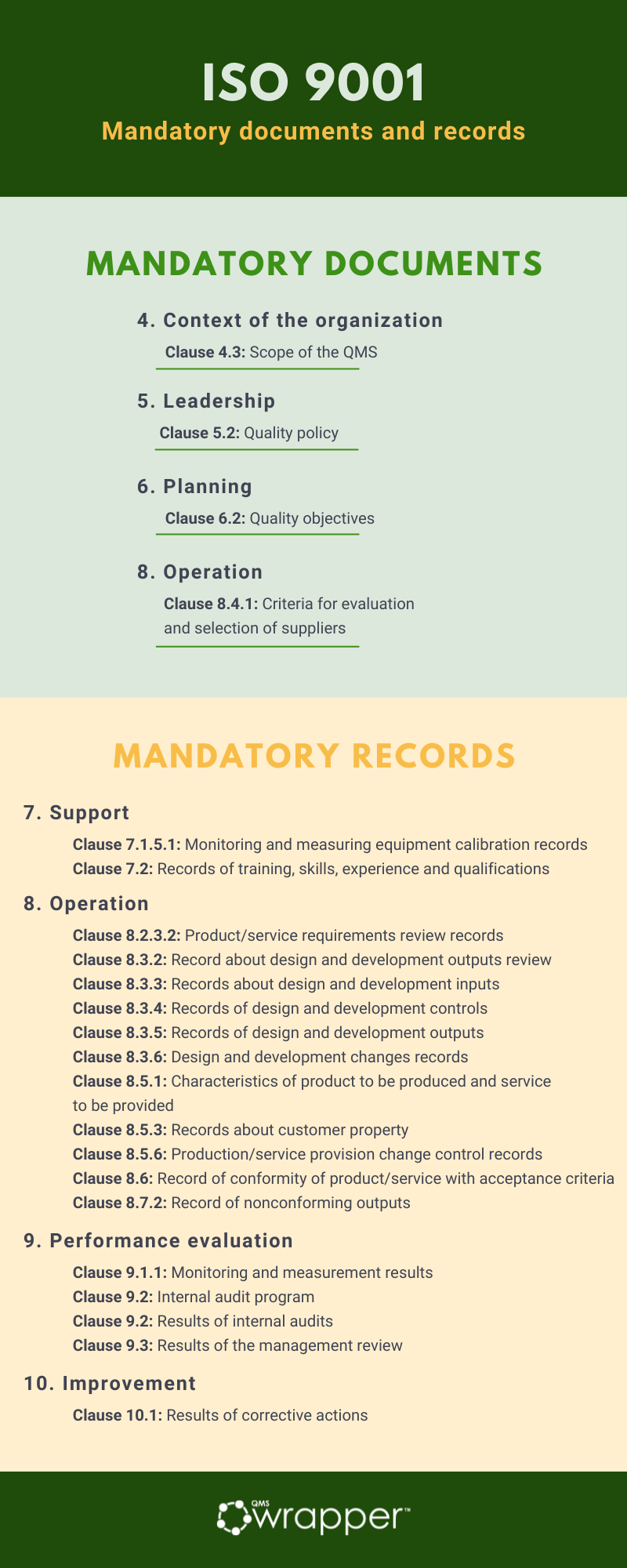

These are the documents to produce in order to be compliant with ISO 9001:2015:

4. Context of the organization

- Clause 4.3: Scope of the QMS

5. Leadership

- Clause 5.2: Quality policy

6. Planning

- Clause 6.2: Quality objectives

8. Operation

- Clause 8.4.1: Criteria for evaluation and selection of suppliers

And, these are the mandatory records:

7. Support

- Clause 7.1.5.1: Monitoring and measuring equipment calibration records

- Clause 7.2: Records of training, skills, experience and qualifications

8. Operation

- Clause 8.2.3.2: Product/service requirements review records

- Clause 8.3.2: Record about design and development outputs review

- Clause 8.3.3: Records about design and development inputs

- Clause 8.3.4: Records of design and development controls

- Clause 8.3.5: Records of design and development outputs

- Clause 8.3.6: Design and development changes records

- Clause 8.5.1: Characteristics of product to be produced and service to be provided

- Clause 8.5.3: Records about customer property

- Clause 8.5.6: Production/service provision change control records

- Clause 8.6: Record of conformity of product/service with acceptance criteria

- Clause 8.7.2: Record of nonconforming outputs

9. Performance evaluation

- Clause 9.1.1: Monitoring and measurement results

- Clause 9.2: Internal audit program

- Clause 9.2: Results of internal audits

- Clause 9.3: Results of the management review

10. Improvement

- Clause 10.1: Results of corrective actions

Please note that some of the documents and records won’t be mandatory if the company doesn’t perform relevant processes.

Non-mandatory documents:

There are numerous non-mandatory documents that can be used for ISO 9001 implementation. So, these are not mandatory, but commonly used in organizations:

4. Context of the organization

- Clauses 4.1 and 4.2: Procedure for determining the context of the organization and interested parties

6. Planning

- Clause 6.1: Procedure for addressing risks and opportunities

7. Support

- Clauses 7.1.2, 7.2, and 7.3: Procedure for competence, training, and awareness

- Clause 7.1.5: Procedure for equipment maintenance and measuring equipment

- Clause 7.5: Procedure for document and record control

8. Operation

- Clause 8.2: Sales procedure

- Clause 8.3: Procedure for design and development

- Clause 8.5: Procedure for production and service provision

- Clause 8.5.4: Warehousing procedure

- Clauses 8.7 and 10.2: Procedure for management of nonconformities and corrective actions

9. Performance evaluation

- Clause 9.1.2: Procedure for monitoring customer satisfaction

- Clause 9.2: Procedure for internal audit

- Clause 9.3: Procedure for management review

A well-structured document system guarantees quality standard is met, reduces the possible errors, reduces downtime when deviations occur due to being able to rapidly access relevant data and allows easy monitoring of the processes. It will improve the organization's efficiency ensuring that its QMS has a strong foundation.

Continual Improvement and Nonconformity and corrective action – Lecture 24

Management review – Lecture 23

Internal audit – Lecture 22